Comprehensive Guide to Air Compressor Supply, Repair, and Maintenance in the Philippines

Introduction to Air Compressors

Air compressors are essential machines that convert power into potential energy stored in compressed air. This process hinges on several mechanisms that utilize electric or gas power to drive a piston or rotor within a cylinder, which compresses atmospheric air, subsequently increasing its pressure. Within the broad spectrum of applications, air compressors are classified into three main types: residential, commercial, and industrial. Each type serves distinct functions tailored to specific environments and user requirements.

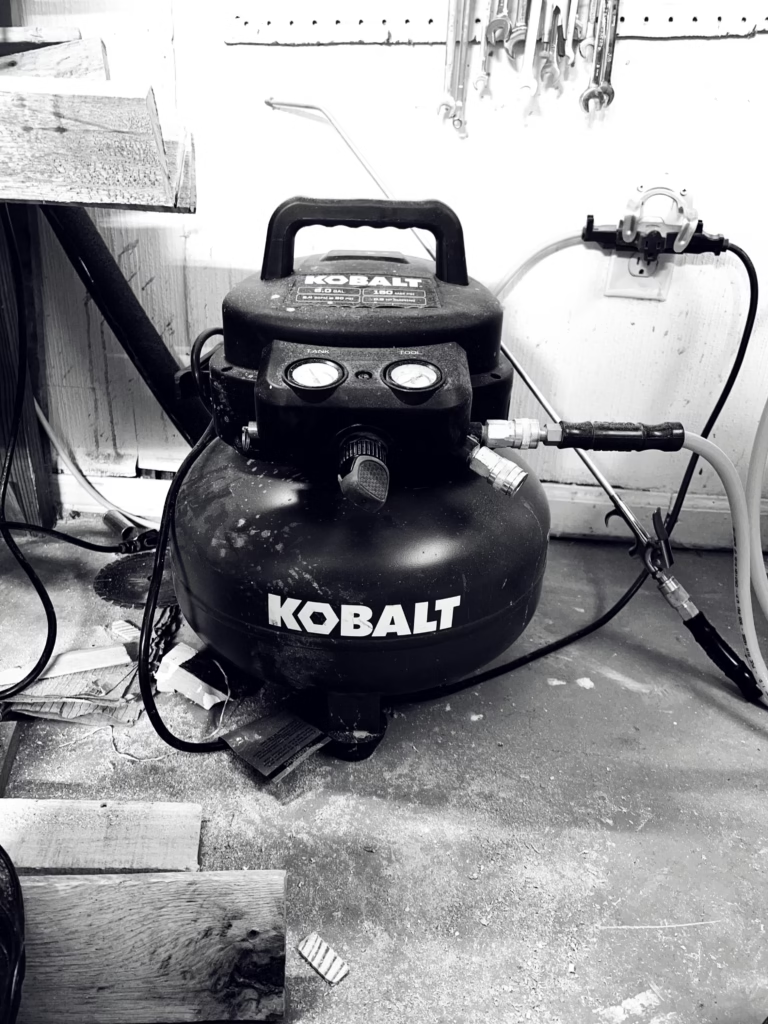

Residential air compressors are typically smaller and intended for home use. They find applications in powering pneumatic tools, inflating tires, and even providing air for hobbies like paint spraying. Commercial air compressors, on the other hand, cater to small businesses, facilitating tasks such as using nail guns or operating automotive repair equipment. These compressors are designed for moderate workloads and often come with additional features enabling better efficiency and noise reduction.

At the industrial level, air compressors play a pivotal role. They are utilized in manufacturing processes where they supply compressed air for various machinery, such as pneumatic drills, conveyor systems, and automated assembly lines. The importance of air compressors in the industrial sector cannot be overstated, as they not only help in improving productivity but also ensure that machines function optimally. Given the diverse applications spread across sectors in the Philippines, the demand for reliable air compressors continues to escalate.

With advancements in technology, modern air compressors are now more efficient and environmentally friendly, reflecting a growing awareness of sustainability within various industries. Understanding the types, mechanism, and applications of air compressors is crucial for both existing users and potential buyers in the Philippines. This knowledge aids in selecting the proper equipment suitable for specific needs, thus maximizing investment and operational efficiency.

Residential Air Compressors: A Home Essential

Residential air compressors serve as invaluable tools in modern households, offering a range of functionalities that significantly enhance daily tasks. Among the most common uses of air compressors in homes includes inflating tires for cars and bicycles, powering air tools, and assisting in the maintenance of various electrical appliances. The versatility of these machines makes them a smart investment for homeowners seeking to streamline tasks efficiently.

When selecting the right air compressor, homeowners should consider their specific needs and the types of tasks they intend to perform. For instance, individuals who require an air compressor primarily for inflating tires may opt for a smaller, portable unit that is easy to store and maneuver. In contrast, those envisioning regular use of pneumatic tools may find it beneficial to invest in a larger, more robust machine capable of delivering higher air pressures and volumes. Understanding the application is vital to making an informed choice.

Moreover, owning a residential air compressor presents several advantages. These machines can offer significant savings over time by enabling homeowners to perform maintenance and repairs without the constant need for professional services. DIY enthusiasts particularly benefit from having access to pneumatic tools powered by air compressors, which can make tasks such as painting, sanding, and woodworking much easier and more efficient.

However, it is important to acknowledge the initial investment associated with purchasing an air compressor. Prices can vary greatly depending on the size, power, and features of the machine. Homeowners should assess their budget while also considering the long-term benefits before making a purchase. Proper research and understanding of specific requirements will guide users toward selecting a suitable air compressor tailored to their household needs.

Commercial Air Compressors: Boosting Business Efficiency

In today’s competitive landscape, small to medium-sized enterprises (SMEs) must leverage every available resource to enhance operational efficiency. One such critical resource is the commercial air compressor, which plays a pivotal role in various industries, including manufacturing, construction, and automotive repair. These compressors are essential for powering pneumatic tools, operating machinery, and performing various tasks that require compressed air, thus ensuring seamless business operations.

Selecting the appropriate size of a commercial air compressor is vital for optimal performance. The compressor should match the air consumption requirements of the tools and machinery utilized within the business. For instance, in a manufacturing setting, equipment such as pneumatic conveyors and spray guns often demand significant air pressure and volume. Consequently, a correctly sized compressor can prevent downtime due to insufficient air supply and enhance productivity. Overly large compressors may lead to unnecessary energy consumption, while undersized models can result in performance issues.

Energy efficiency is another significant factor when considering commercial air compressors. With rising energy costs, choosing an energy-efficient model can lead to substantial savings over time. Look for compressors that comply with industry standards and possess energy-saving features, such as variable speed drives or efficient motors. Investing in energy-efficient models not only reduces operational costs but also contributes to environmental sustainability, aligning with corporate social responsibility goals.

Finally, businesses must adhere to regulatory compliance when operating air compressors. Occupational Safety and Health Administration (OSHA) guidelines dictate safety practices to minimize the risk of accidents associated with compressed air systems. Compliance with local regulations is crucial for avoiding potential penalties and ensuring a safe working environment for employees. In this context, businesses must prioritize regular maintenance and inspections of their commercial air compressors to sustain operational reliability and compliance with applicable standards.

Industrial Air Compressors: The Heart of Manufacturing

Industrial air compressors play a pivotal role in the manufacturing and production industries, serving as the backbone of various processes. These high-capacity machines are designed to meet the significant demands of large-scale operations, providing a reliable power source for an array of applications, including pneumatic tools, material handling, and system automation. In the context of manufacturing, the efficiency and durability of air compressors have a direct impact on production timelines and overall operational effectiveness.

Modern industrial air compressors feature sophisticated technology that enhances their performance and reliability. Advances in design and engineering have led to the development of energy-efficient models capable of delivering consistent pressure and performance under extreme conditions. As production needs evolve, manufacturers are increasingly choosing rotary screw compressors and reciprocating compressors, known for their ability to handle varying workloads while maintaining optimal efficiency levels. These advanced features not only contribute to increased productivity but also reduce operational costs, making them a smart investment for manufacturing companies.

To fully leverage the capabilities of industrial air compressors, effective maintenance practices are essential. Regular scheduled maintenance helps to ensure that these machines operate at peak performance, minimizing downtime and extending their longevity. Key maintenance activities include routine inspections, cleaning or replacing filters, checking oil levels, and examining belts and hoses for any signs of wear. Proper lubrication is also critical to reducing friction, which can lead to significant wear and tear. By investing in preventive maintenance, manufacturers can avoid costly repairs and minimize the risk of unexpected breakdowns, ultimately enhancing the overall efficiency of their production lines.

Choosing the Right Air Compressor for Your Needs

Selecting the appropriate air compressor is a crucial step that can significantly affect your work efficiency and overall satisfaction. Understanding your specific requirements is essential, as various types of tasks demand different features and capabilities. The first factor to consider is the power requirement of the compressor. This is typically measured in horsepower (HP) or cubic feet per minute (CFM). For instance, light-duty jobs may only necessitate a small, portable unit, while heavy-duty applications might require a more powerful compressor with a higher CFM rating.

Next, the tank size is an important aspect to deliberate upon. Compressors come with varying tank sizes, and choosing one depends on the duration of your usage. A larger tank can store more air, enabling continuous operation without frequent cycling on and off, which is particularly beneficial for tasks like spray painting or sandblasting.

Portability is another key factor, especially for those who need to transport the air compressor frequently. If mobility is a priority, consider a lightweight model or one with wheels. Conversely, if the compressor will remain stationary, then size may not be as critical.

Noise levels also warrant attention, particularly in residential or workplace environments where sound restrictions might apply. Some compressors are designed for quieter operation, which might be more suitable if noise is a concern. Lastly, budget constraints cannot be overlooked. Prices can vary significantly based on brand, specifications, and additional features. Assessing your budget and aligning it with your specific needs can guide you toward the best possible choice.

Overall, by carefully evaluating power requirements, tank size, portability, noise levels, and cost, you can make an informed decision that will meet your air compressor needs efficiently.

Air Compressor Repair and Common Issues

Air compressors are essential tools widely used across various industries, providing compressed air for diverse applications. However, like all machinery, they are susceptible to malfunction, leading to various common problems that users might encounter. Recognizing these issues early on can prevent further damage and costly repairs. This section discusses frequent symptoms and their respective diagnoses and remedies.

One prevalent issue is insufficient pressure, which can arise from several factors. Users may notice that the compressor fails to maintain the required pressure levels. This situation might stem from a leak in the air hose or fittings, a malfunctioning pressure switch, or a declination in the compressor’s overall performance. To diagnose the problem, visually inspect all hoses for leaks, and listen for hissing sounds during operation. Repairing leaks typically involves replacing the damaged components, while addressing pressure switch concerns may necessitate recalibration or replacement.

Another common symptom is the presence of unusual noises, such as grinding or rattling sounds. These noises can indicate loose components or worn-out bearings. Users should perform regular maintenance checks on bolts and screws to ensure they are tightly secured. Additionally, lubricating moving parts can mitigate noise levels and prolong the service life of the air compressor. If the noises persist despite these measures, it may be necessary to consult a professional for a more thorough inspection.

Overheating is yet another issue that can compromise an air compressor’s performance. Continuous operation without appropriate breaks can lead to elevated temperatures. Users should ensure that the compressor’s cooling system is functioning efficiently and that there are adequate air vents. Regular cleaning and maintenance protocols help prevent this issue from recurring, as debris accumulation can impede airflow. By adhering to these preventive measures, users can enhance the longevity and reliability of their air compressors.

Preventive Maintenance for Longevity

Preventive maintenance plays a pivotal role in extending the lifespan of air compressors, ensuring they operate efficiently and without interruption. A well-structured maintenance plan not only aids in identifying potential issues early but also significantly reduces the risk of costly repairs and unexpected downtime. Regular inspections are essential; they should be conducted at predetermined intervals to assess performance, check for leaks, and ensure all components are functioning as intended. Such assessments help in maintaining optimal air quality and pressure levels.

Oil changes are another critical aspect of the preventive maintenance checklist. The lubrication system, which reduces friction and wear between moving parts, requires fresh oil to maintain its effectiveness. It is advisable to refer to the manufacturer’s guidelines regarding the frequency of oil changes, as neglecting this vital task can lead to excessive wear and potential equipment failure. Additionally, the type of oil used can greatly affect the performance and longevity of the air compressor, so selecting the appropriate oil is crucial.

Filter replacements are equally important in the maintenance regimen. Air and oil filters accumulate debris over time, which can hinder airflow and reduce compressor efficiency. By routinely replacing these filters, one can ensure that the air compressor operates at maximum efficiency and reduces the risk of malfunctions. Cleaning the compressor and its components also contributes to its longevity; removing dust and dirt buildup not only prevents corrosion but also enhances airflow and cooling efficiency.

Incorporating these preventive maintenance tasks into a regular schedule can yield considerable savings in the long term. By adopting a proactive approach to maintenance, air compressor users in the Philippines can experience fewer disruptions and extend the overall life of their equipment, thus achieving a more reliable operation. Regular maintenance is not just an expense; it is a wise investment in the longevity and efficiency of air compressors.

Where to Find Reliable Air Compressor Services in the Philippines

Finding dependable air compressor services is crucial for ensuring optimal performance and longevity of your equipment. In the Philippines, various options are available for sourcing air compressors, including both local suppliers and online marketplaces. Local suppliers often provide the advantage of immediate support and personalized service. Many of these suppliers are well-established companies that have built a reputation for reliability in the industry. It is advisable to visit these suppliers directly to inquire about their range of products and repair options, as well as to assess their customer service capabilities.

In addition to local outlets, online marketplaces such as Lazada and Shopee have emerged as popular alternatives for purchasing air compressors. These platforms typically feature a wide array of brands, models, and price ranges, making it easy for consumers to compare options from the comfort of their home or office. However, when using online sources, it is imperative to pay close attention to vendor ratings and consumer reviews. This will help ensure that you are procuring a high-quality product from a trustworthy source.

Beyond sourcing, choosing reputable brands is vital for the long-term satisfaction with your air compressor. Leading brands often have dedicated customer service teams and warranty provisions that can address queries and concerns promptly. For maintenance and repair services, it is essential to select providers with certifications and experience in handling different types of air compressors. Many businesses have benefitted from maintaining relationships with reliable service entities that offer routine check-ups and emergency repairs, contributing significantly to the uninterrupted functionality of their compressors.

In conclusion, both local and online options exist for acquiring air compressors and associated services in the Philippines. By prioritizing reputable suppliers and skilled service providers, businesses can ensure the sustained operation of their essential equipment.

Conclusion: Maximizing the Value of Air Compressors

Throughout this guide, we have explored the multifaceted world of air compressors, focusing on their supply, repair, and maintenance within the context of the Philippines. Understanding the various types of air compressors available, such as reciprocating, rotary screw, and centrifugal compressors, is crucial for selecting the right system to meet specific operational needs. Each compressor type offers distinct advantages and is suited for various applications, emphasizing the importance of making informed decisions based on one’s requirements.

In addition to selecting the appropriate compressor, maintaining these machines is paramount for ensuring their longevity and efficiency. Regular maintenance practices, including routine inspections, filter changes, and lubrication, not only prevent breakdowns but also enhance performance. Owners and operators are encouraged to adhere to maintenance schedules and consult professional technicians when necessary, thereby reducing the likelihood of unplanned downtime and repair costs.

Equally important is the choice of service providers. Collaborating with reputable companies for repair and maintenance services can significantly impact the performance of your air compressor. These professionals often bring valuable expertise and access to quality replacement parts, fostering an environment where your system can operate at peak efficiency. Establishing a partnership with reliable service providers ensures quick response times and minimizes the inconvenience of compressor failures.

As you assess your operational needs, consider evaluating your current air compressor setup and determine if it meets your performance standards. Identifying potential improvements or upgrades can optimize productivity while reducing energy costs. By understanding the dynamics of air compressor supply, repair, and maintenance, you position yourself to maximize the value of your investment in air compressor technology.

- June 13, 2025

- 327

- Construction and Engineering , Engineering , Technology

- 0 comment

Add Comment